For instance, the orientation of HMCs makes it possible for chips to drop absent By natural means, so you don’t really need to waste time clearing them off the desk. For maximum efficiency, you can even set up an HMC on the pallet while loading get the job done on to a independent pallet.

Every of those components and tools is crucial to the milling operation, as they collectively empower the machine to fabricate parts with exacting tolerances and wonderful finishes.

The constructions it supports best are flat surfaces, threads, and round parts with an interior and outer diameter.

The supplier's working experience from the industry frequently correlates with their power to deal with intricate initiatives and provide useful insights. They should Have got a tested track record with initiatives that display their abilities.

Alan is a qualified writer and hobbyist in CNC technology, and brings an intensive history to his crafting at CNCSourced. He has many decades of working with hobbyist machines like laser cutters and CNC routers, as well as a diploma in Mechanical Engineering and various certifications.

B As well as is usually a vertical machining center offered in conventional and also Sophisticated small, medium and large types. The ROBODRILL As well as presents the flexibility to take care of an array of machining programs for large or small manufacturers.

In five-axis machining, your part and workholding ought to have the capacity to rotate and tilt within the workspace, allowing for you to succeed in all parts of the part, without interference or collisions. This yields a cylindrical operate envelope that's smaller in comparison to the machine travels.

Spindle: The spindle is an important element liable for Keeping and rotating the milling tools. It will vary in pace, electricity, and torque dependant upon the machine's capabilities.

CNC milling operations encompass a wide array of procedures that accomplish diverse outcomes in precision machining. Restricted tolerances are taken care of, making sure high-quality and complex parts are produced with amazing accuracy.

A machining center is a complicated machine Instrument that permits the machining of parts, typically metal, by product removal. Usually we make reference to milling or machining inside of a basic way. This guidebook focuses on CNC (Personal computer Numerical Control) machining centers and milling machines.

How to select Decision will depend upon maximum workpiece measurement and also the rotational pace of the primary spindle.

Every content provides a list of Houses that cater to particular wants, for instance thermal resistance in ceramics or Visible clarity in glass. The last word determination really should align with the purposeful requirements of the top product while also contemplating the financial efficiency in the machining system.

Programming and operation of the CNC milling machine involve converting CAD styles into CNC programs that control the machine's movements for several operations like machining, drilling, or turning.

The used CNC machines for sale listed more info here use computer-pushed commands to control cutting tools and equipment motion. Our inventory handles a variety of equipment, Every perfect for distinctive purposes, from CNC grinders to CNC lathes.

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Romeo Miller Then & Now!

Romeo Miller Then & Now! Kelly Le Brock Then & Now!

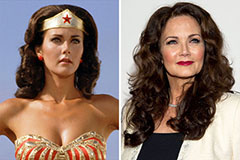

Kelly Le Brock Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now!